Advanced Processing Equipment

And Experienced Technical Team

Jinhuili Valve Co., Ltd. is a manufacturer specializing in the research, development, production, and sales of hard-sealed ball valves designed for severe working conditions, including high temperature, ultra-low temperature, and low temperature environments. All products are manufactured in compliance with GB, ANSI, API, DIN, BS, and JIS standards, and the company also undertakes the design and production of various non-standard valves. The materials used include stainless steel, WCB, WC6, WC9, LCB, CF8, CF8M, CF3, CF3M, 904L, A105, F304, F316L, F11, F904L, 2520 (310S), 2205 (4A), 2507 (5A), CN7M, nickel alloys, TA2 titanium, Zr zirconium, HC Hastelloy, Monel alloys, and other specialized materials.

Our products are widely applied in industries such as coal chemical engineering, petroleum, refining, natural gas, polysilicon production, chemical engineering, metallurgy, and electric power. They are highly sought after across the domestic market and are also exported overseas, earning the trust and recognition of our customers.

The company has strong technical and processing strength. CNC machining equipment, plasma surfacing, spraying, precision ball and seat grinding equipment. Complete testing equipment, complete testing means, with CAD computer center, physics laboratory, measuring room, chemical analysis room; ISO9001 international quality system standard to ensure the whole process of product quality control, for the quality control ability and enterprise management level has laid a solid foundation

The company has accumulated rich production experience in the process of continuous development and innovation, and has always been committed to improving its engineering supporting capabilities and innovation capabilities, so as to be able to provide a full set of valve solutions for various new industrial needs. Adhering to the quality policy of "focusing on customers, creating brands, serving with integrity, and continuous improvement", the product quality is reliable and enjoys a high reputation among customers. The company regards quality as life, survives by reputation, promotes development by science and technology, and serves users with high-quality products. We sincerely welcome friends from all walks of life to visit our company for inspection and guidance, conduct technical cooperation and exchanges, and create the company's beauty and glory together.

Forging Process

Casting Process

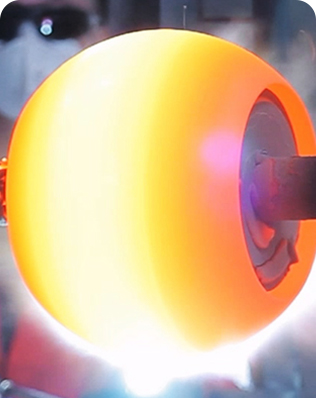

Spraying Process

Processing Technology

- Production Control

- Physical and Chemical Experiment

- Inspection Site

- Product Site

The company also specializes in the design and production of various non-standard valves,

utilizing materials such as stainless steel, aluminum, titanium, 316, 316L, 304, 304L, 2520, WCB, among others.

supported by a rigorously trained quality management team. This ensures quality control across the

entire process, from raw material testing and production process monitoring to product inspection and application evaluation.

achieving comprehensive quality control throughout the entire process, from raw material testing and

production to product application. This provides stronger assurance for enterprise innovation and product quality.

- Qualification Certificate

- Patent Certificate

- Certificate of Honor